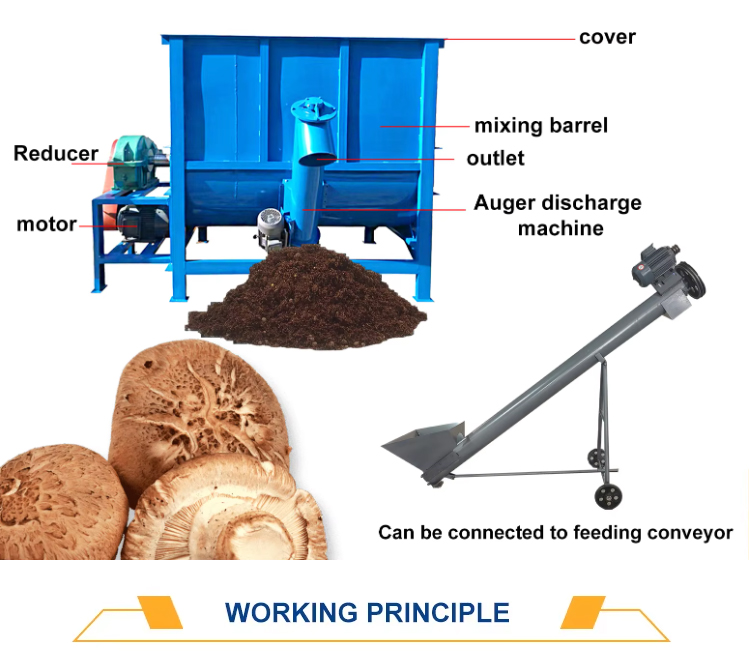

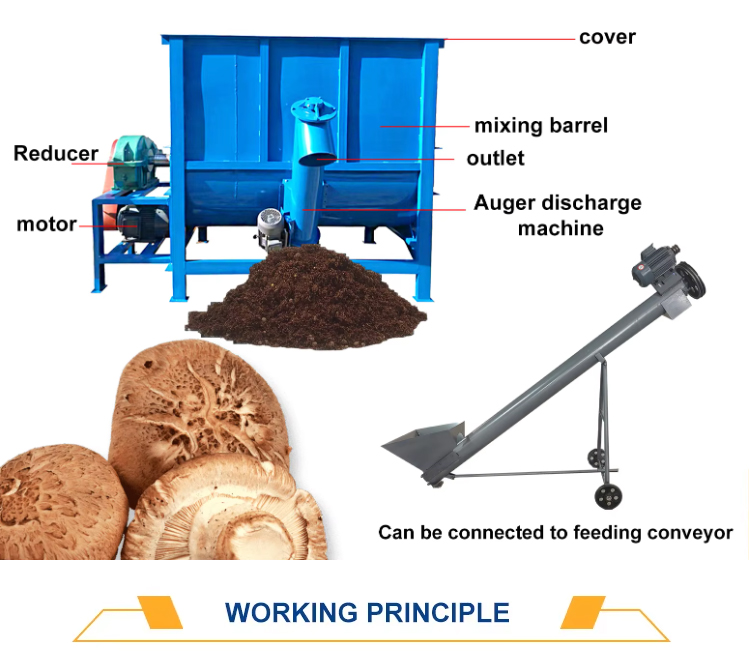

The horizontal mixer is practical and has a wide range of applications. It consists of a mixing ribbon (can also be paddle-type), a U-shaped barrel, a frame, a power unit, an electric control box and other parts.The mixer is a horizontal barrel with stable operation, easy installation and maintenance, high mixing uniformity, fast mixing speed, high mixing uniformity, and can mix both dry and wet materials.For different materials and mixing amounts, you can freely choose the machine material and mixing volume, such as carbon steel, stainless steel, and a variety of models of mixing volume. The horizontal mixer can be equipped with a variety of feeding and discharging methods

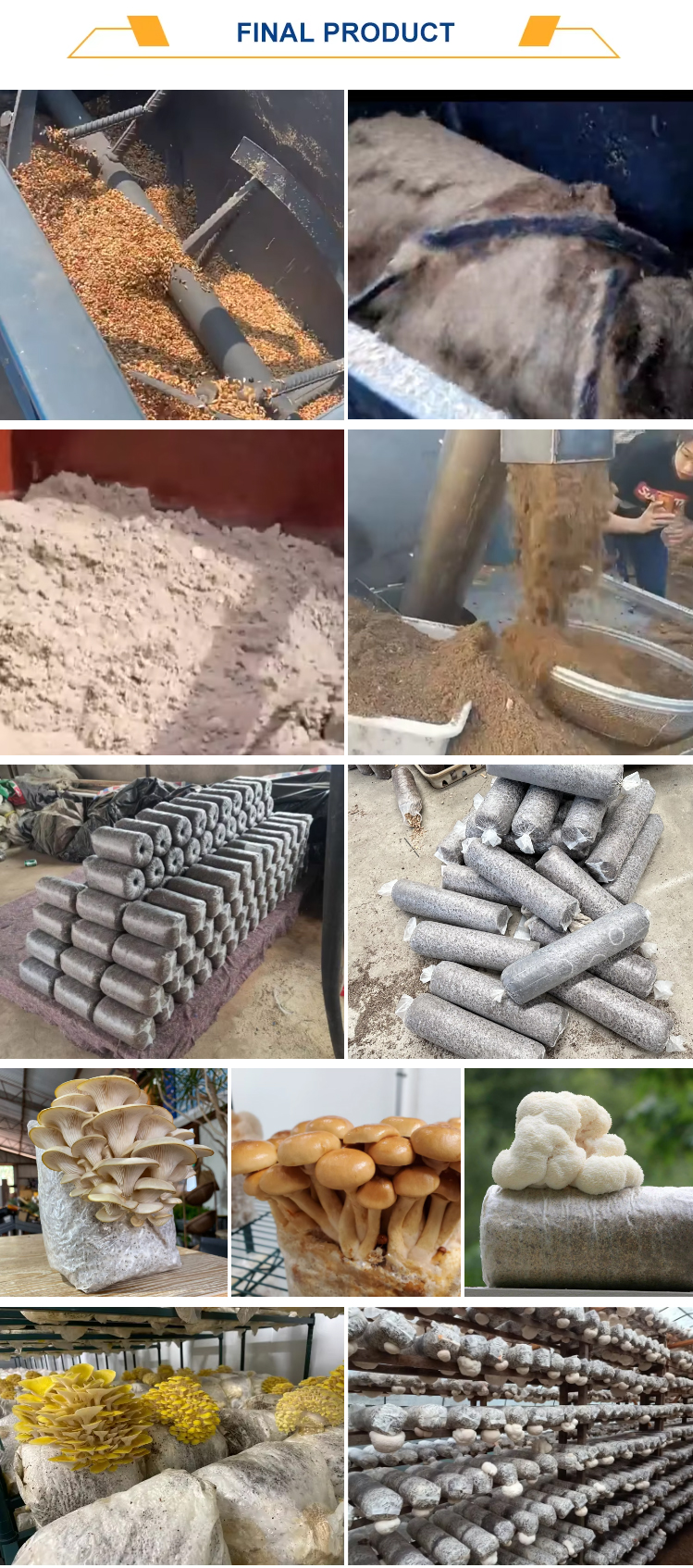

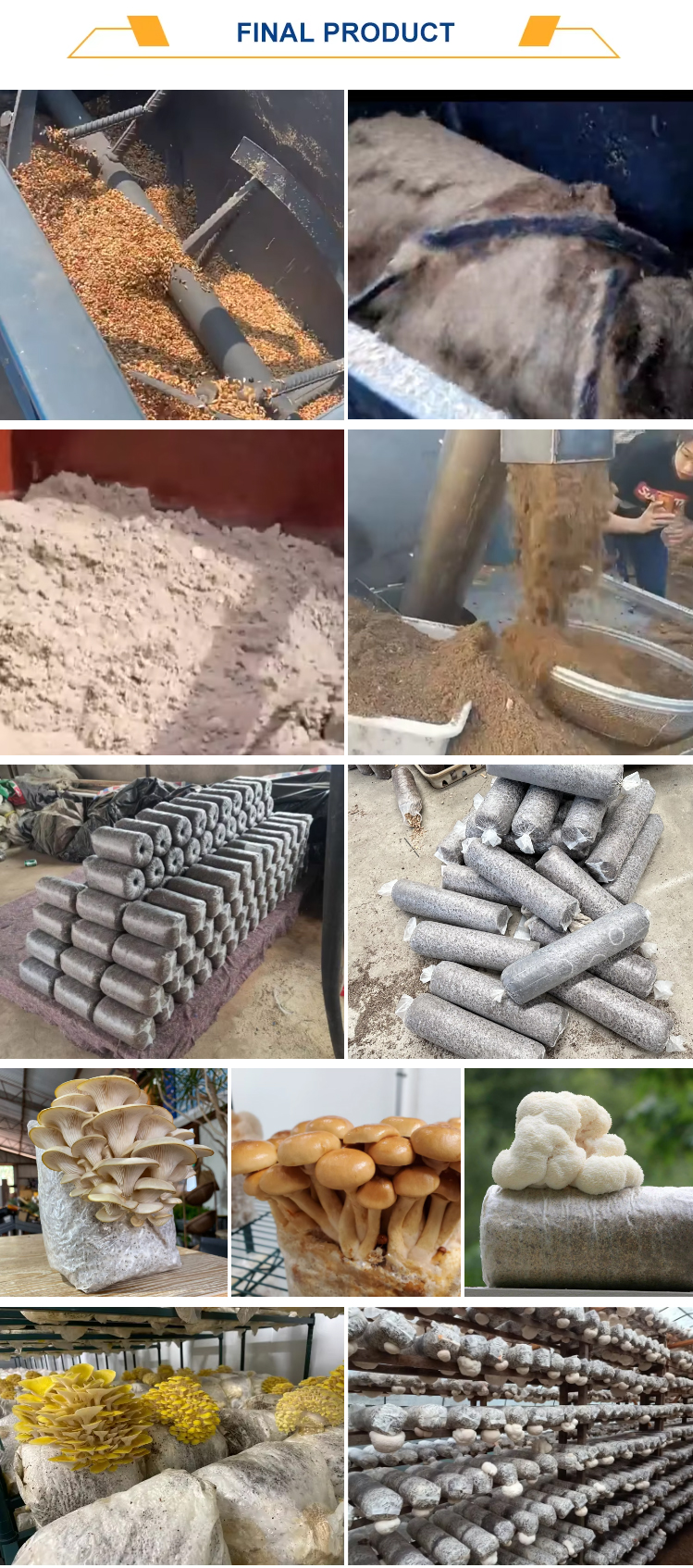

It is mainly suitable for mixing feed, mixing grain particles, mixing particles and powders in various industries such as chemicals, dry powder, mortar, and mushroom cultivation.

ŌæĀ | When the horizontal mixer is working, start the equipment first, then put in the materials |

ŌæĪ | When the materials enter the mixer barrel, they are evenly stirred by the inner and outer double-layer S-shaped stirring spiral ribbon of the mixer. The outer spiral ribbon moves in opposite directions to the inner spiral ribbon, so that the materials form convection alternating stirring. The homogenization stirring time for each batch is about 5-15 minutes. There are large differences in various materials and material proportions, so the actual time shall prevail. |

Model | JCJB-300L | JCJB-440L | JCJB-1000L |

Volume | 300L | 440L | 1000L |

Mixing time | 5-10minutes/batch | 5-10minutes/batch | 5-10minutes/batch |

Power | 3KW | 4kw+1.5kw /380v,50hz, 3phase | 4kw+1.5kw /380v,50hz, 3phase |

Weight | 250kg | 350kg | 500kg |

Size | 1700*630*1450mm | 1900*850*1400mm | 1900*850*1400mm |

Packing size | 2250*950*1800mm (3.8CBM) | 2250*950*1800mm (3.8CBM) | 2250*950*1950mm (4.2CBM) |

Inner size | 1000*500*720mm | 1200*550*720mm | 1500*800*920mm |